- WhatsApp: +8619816263196

- carol@beltscaleintegrator.com

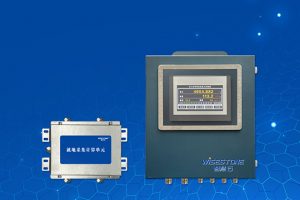

The belt scale weighing instrument is also called the weighing control display. Its main function is to convert the weighing sensor signal (or through the weight transmitter) into a weight digital display, and can store, count, and print (part of the instrument) the weight data. It is an electronic device that is often used in industrial and agricultural production for automated weighing, quantitative feeding, and system batching to improve the daily production efficiency of enterprises.

So, what should be paid attention to during the installation and use of the belt scale weighing instrument? Today, I will give you a brief explanation on this issue:

First: During the installation process, it is necessary to pay special attention to the fact that a clean, dry, ventilated, and temperature-appropriate environment must be selected. It is best to choose a suitable space to fix the instrument. It should not be moved frequently, otherwise it will cause the internal lead of the signal cable plug to fall off and cause a malfunction.

Second: Pay attention to the power supply. Generally speaking, most belt scale instruments use a 220V AC power supply, and the voltage range allowed is generally 187V-242V. Remember that after changing the power supply line, you must first measure whether the voltage meets the requirements before you can power on the instrument, otherwise it may cause damage to the instrument. In addition, in situations where the power supply voltage fluctuates greatly, a voltage stabilizer with good performance should be equipped to ensure the normal use of the instrument. Do not use the same power socket as a strong interference source to avoid unstable display values of the instrument.

Third: Pay attention to the grounding problem. The belt scale weighing instrument should be connected to an independent and good grounding wire. The instrument grounding has two functions. One is to protect the personal safety of the operator, and the other is to play an anti-interference role to ensure the stable operation of the instrument. It should be noted here that the relevant staff should regularly check whether the ground connection point is in good contact.

Fourth: Sun protection of belt scale instruments: Avoid direct sunlight on the black shell of the instrument, otherwise the working environment of the instrument may exceed the rated temperature range and be damaged.

Fifth: Waterproof: Under normal circumstances, the humidity of the instrument working environment can reach 95%, but it is stipulated that condensation cannot be generated. Special stainless steel shell instruments with waterproof function are an exception.

Sixth: Anti-corrosion: If corrosive substances penetrate into the instrument, it may cause corrosion of the components on the circuit board and the circuit board itself, which will cause the instrument to be scrapped over time. The main thing to note here is that even if the instrument has anti-corrosion function, if it is not tightly sealed, it will also cause the same result.

Seventh: Lightning protection: We all know that electronic scales belong to weak current systems and are easily attacked by lightning and damaged components. Therefore, it is necessary to take lightning protection measures for belt scale instruments.

Eighth: Strong electricity protection: The impact of strong electricity on belt scale instruments cannot be ignored. For example, if the live wire of a power supply above 220 volts is accidentally connected to the equipment as a ground wire, or electric welding is performed on the equipment, it may damage the instrument.

Ninth: Cleaning: In an industrial environment, there will be dust or contamination on the instrument casing, and it must be wiped clean frequently with a wet rag when the power is off. It should be noted here that you must not wipe the display window with solvents such as alcohol, which will deteriorate the light transmittance and make the display blurred.

The above are the main matters to be paid attention to during the installation and use of belt scale weighing instruments. In addition to the above problems, belt scale instruments must also be regularly maintained and maintained to ensure the normal and stable operation of the instrument and even the entire belt scale equipment.