- WhatsApp: +8619816263196

- carol@beltscaleintegrator.com

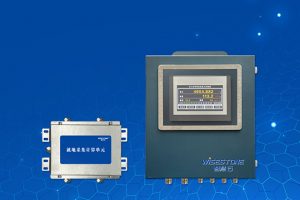

The WSD-1000 series belt scale meter is specially designed for belt scales and can meet the needs of all measurement and control functions. The software part of all functions of the meter is solidified into the memory chip. When the user installs the optional expansion board or the operator selects through the keyboard, the weighing display controller will automatically open the corresponding function. Today, the measurement functions of this series of meters are explained as follows.

The measurement functions of the WSD-1000 series belt scale meter mainly include instantaneous flow calculation, flow accumulation, automatic zero adjustment and automatic interval adjustment, automatic zero tracking and current output signal, etc.

First: instantaneous flow calculation. When it comes to instantaneous flow, we must first understand what instantaneous flow is. In fact, what we usually call instantaneous flow refers to the weight information (kg/m) of the unit belt length output by the weighing sensor multiplied by the belt speed (m/s) output by the speed sensor. The result is the instantaneous flow (kg/s). By multiplying the instantaneous flow by an appropriate constant, it is converted into an engineering unit value, which is provided to the flow display and current output respectively through an appropriate attenuation filter.

Second: flow accumulation. The cumulative amount refers to the accumulation of weight per unit length and running time, which is then converted into engineering units. There are two ways to store the cumulative amount: the first storage method (main cumulative amount) ensures that it will not be reset and the data will not be lost; the second storage method (reset cumulative amount) is used for normal shifts and daily accumulation, and the operator can clear it.

Third: automatic zeroing and automatic interval adjustment. First of all, it should be clear that defining the belt length by the number of belt turns is the basis for automatic zeroing and automatic interval adjustment.

To accurately calculate the belt length, the instrument calculates the number of pulses sent by the speed sensor (one pulse number represents a specific belt length). When the required number of pulses is accumulated, the instrument ends the calibration test, compares the theoretical value with the actual value, and accumulates the calibration constant.

Fourth: automatic zero tracking.

When the belt is running, the flow rate is lower than the preset value, and the calculator automatically adjusts to zero according to the following steps:

1. Wait for half of the test cycle (flag display)

2. Complete a zero test (flag display)

3. Complete automatic zeroing of a test cycle

4. As long as the flow rate continues to be lower than the preset value, repeat the above zero calibration.

The zero tracking function has a maximum limit "zero tracking range", which is set in percentage in the calibration data menu. If the current flow rate percentage exceeds the zero tracking range, the zero tracking automatically exits.

Fifth: Current output signal. The optional current expansion board can provide one 4-20ma current input signal and two 4-20ma current output signals. The output signal can be set through the keyboard and represents one of the following signals: instantaneous flow, belt load and control signal.