- WhatsApp: +8619816263196

- carol@beltscaleintegrator.com

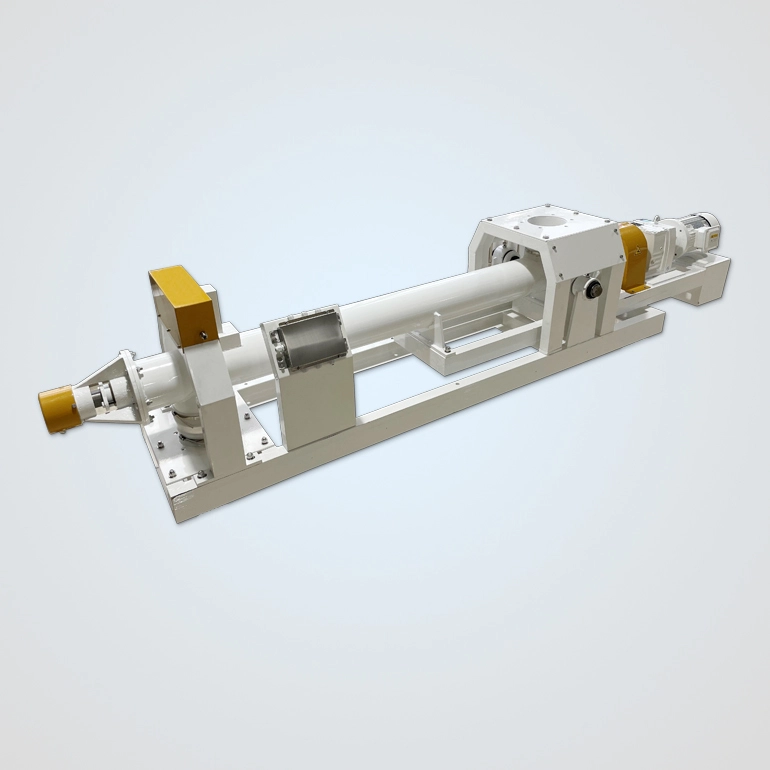

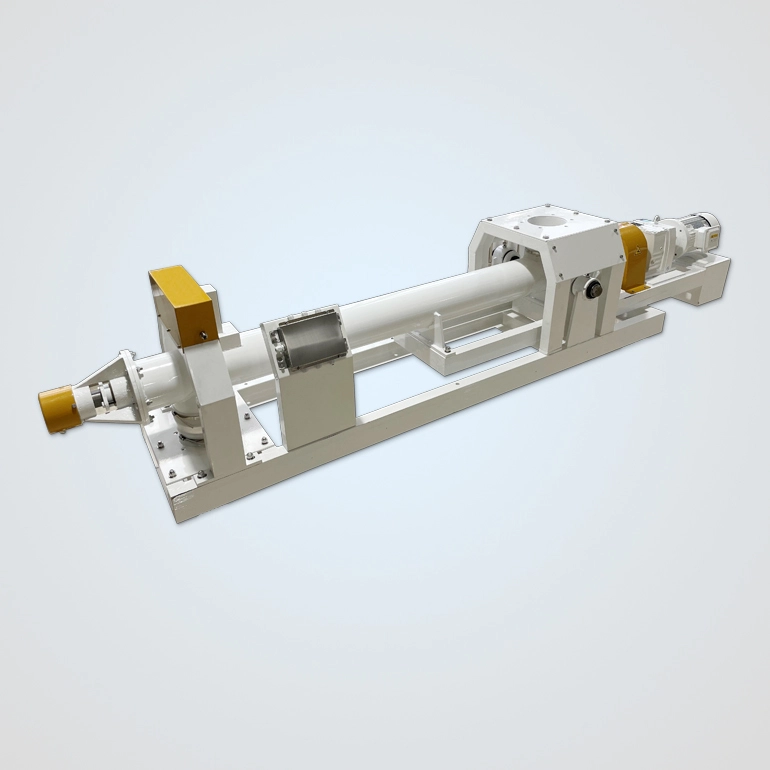

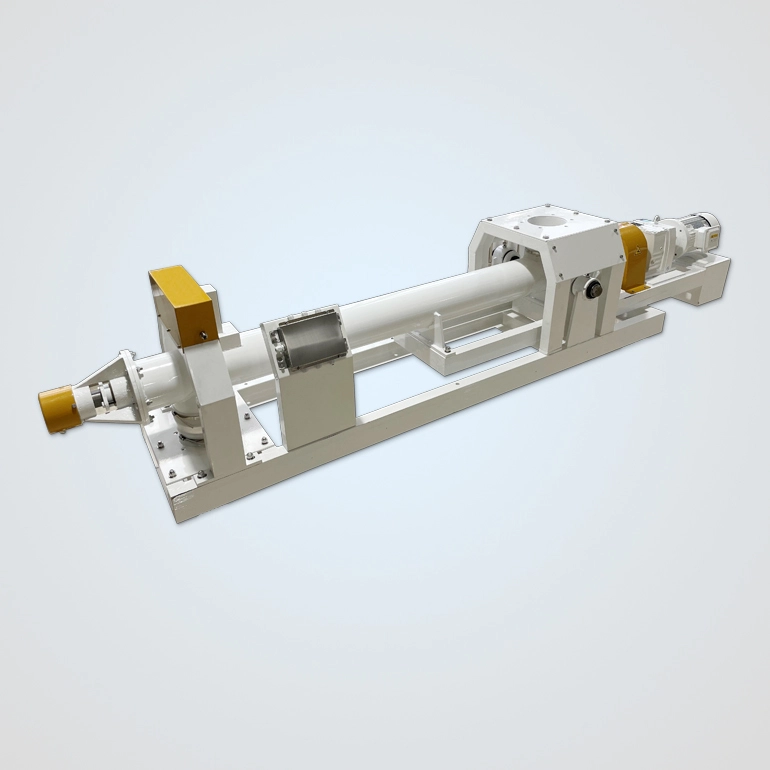

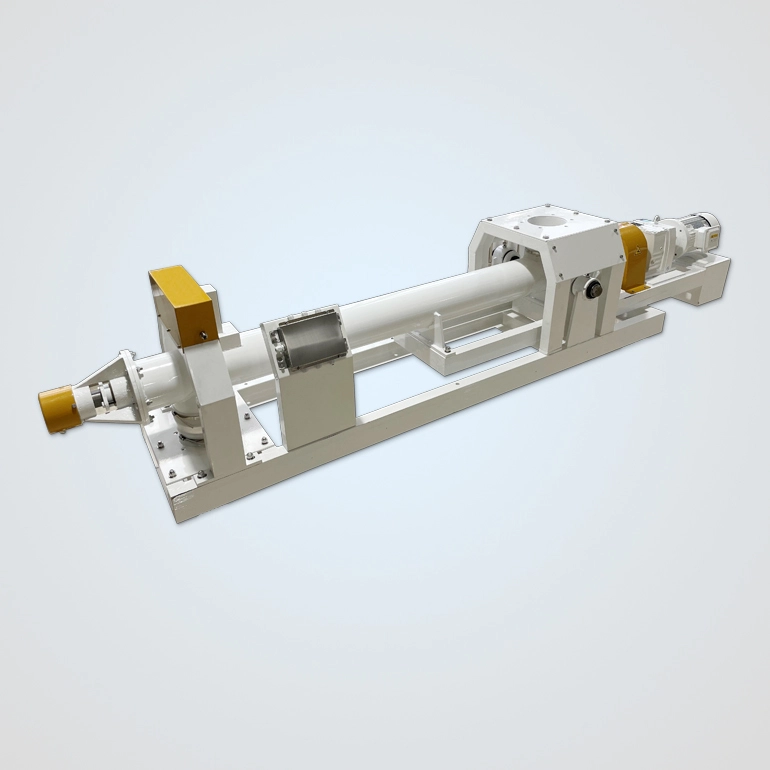

WSD-JSX Double belt weigh feeder

Working Principle:

Working Principle:

When the material is being conveyed by the screw conveyor, the weighing sensor installed under the screw conveyor detects the weight of the material and generates a voltage signal proportional to the load. At the same time, the speed sensor installed at the tail of the screw conveyor detects the speed signal of the main shaft of the screw conveyor. The two signals are sent to the weighing integrator at the same time, and the instantaneous flow value and the cumulative value are obtained after integration operation.

Reliable variable frequency speed regulation technology

Reliable variable frequency speed regulation technology

Adopting international first-line inverter and high-performance vector control technology, it has a wide speed regulation range and fully meets the quantitative batching control needs.

Special design of inlet and outlet ensures smooth feeding

Special design of inlet and outlet ensures smooth feeding

The flow-stabilizing spiral adopts variable pitch structure and outlet overflow method, which effectively solves the problem of material impact. With variable diameter, variable pitch and overflow outlet, the material sinks evenly, is stably controlled, and does not collapse, expand or smear.

Touch-type intelligent controller

Touch-type intelligent controller

Intelligent control instrument specially developed for spiral batching system, with whole machine EMC design and strong anti-interference ability, especially suitable for industrial batching environment. Unique anti-vibration filtering algorithm, high-frequency sampling, fast response, meeting high-precision and production requirements.

High-precision digital weighing module

High-precision digital weighing module

One or three high-precision weighing sensors can be selected according to the on-site working conditions. It adopts digital transmission technology, has simple circuits, no adjustment components, high resolution, no signal attenuation, strong anti-interference, and can maintain excellent sensitivity even in humid environments.

Parameters

Parameters

| Model | Pipe diameter | Center distance | Hourly output | Use precision | Motor power |

| WSD-LXC-150 | 150mm | 1600mm~4500mm | 4~7.5m³/h | ≤0.2% or 0.5%~1% | 1.1~3kW |

| WSD-LXC-200 | 200mm | 1600mm~4500mm | 12~23m³/h | ≤0.2% or 0.5%~1% | 1.1~4kW |

| WSD-LXC-250 | 250mm | 1600mm~4500mm | 24~46m³/h | ≤0.2% or 0.5%~1% | 2.2~4kW |

| WSD-LXC-300 | 300mm | 1600mm~4500mm | 30~58m³/h | ≤0.2% or 0.5%~1% | 2.2~4kW |

| WSD-LXC-350 | 350mm | 1600mm~4500mm | 37~40m³/h | ≤0.2% or 0.5%~1% | 2.2~5kW |

| WSD-LXC-400 | 400mm | 1600mm~4500mm | 50~95m³/h | ≤0.2% or 0.5%~1% | 2.2~7.5kW |

Downloads

Downloads

Related

Related