- WhatsApp: +8619816263196

- carol@beltscaleintegrator.com

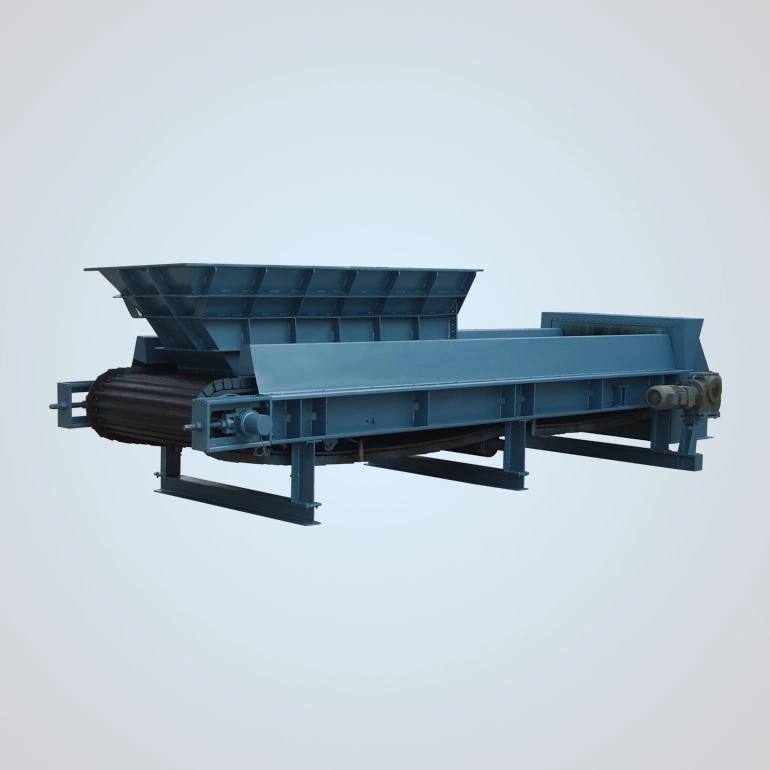

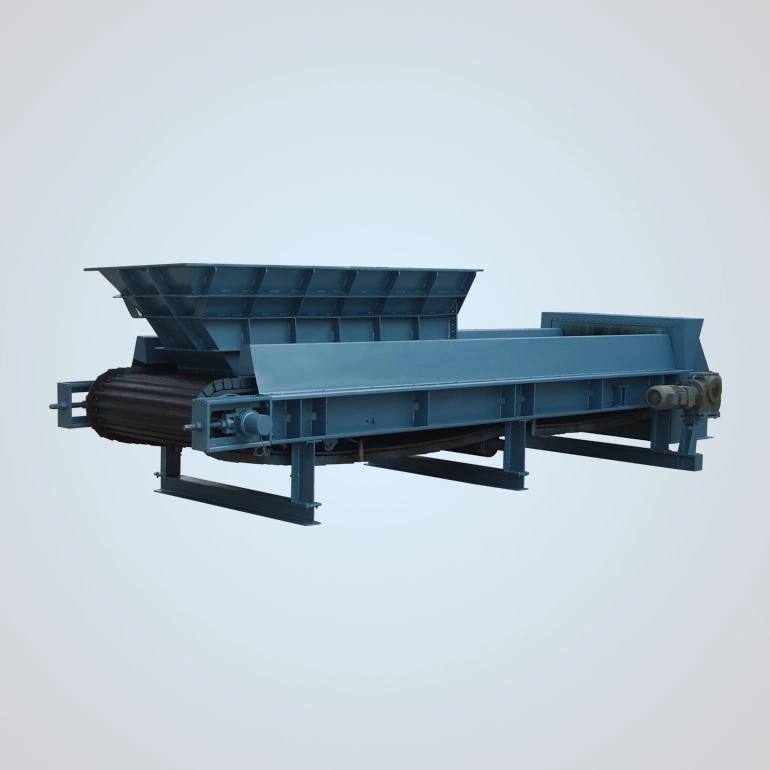

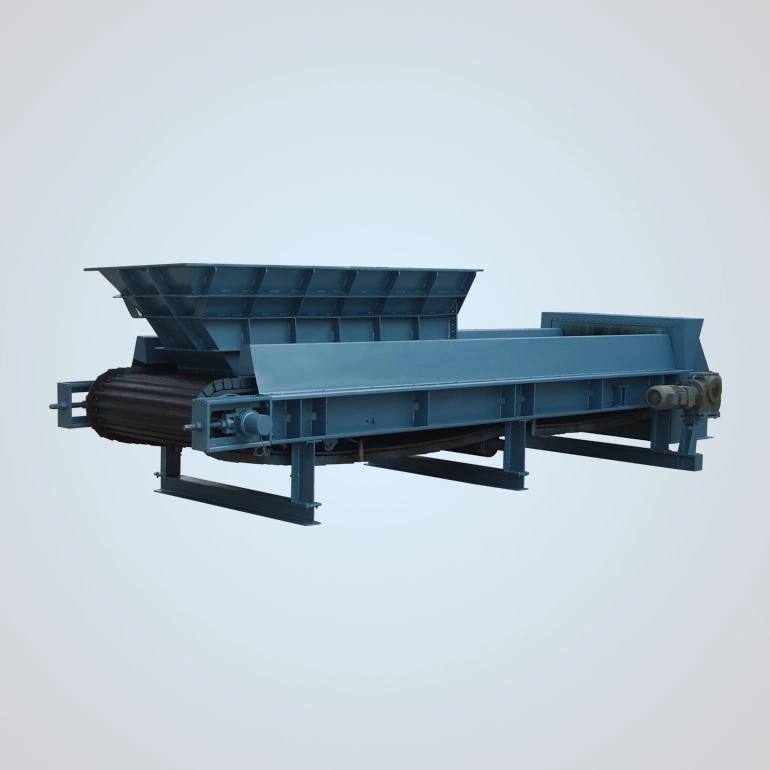

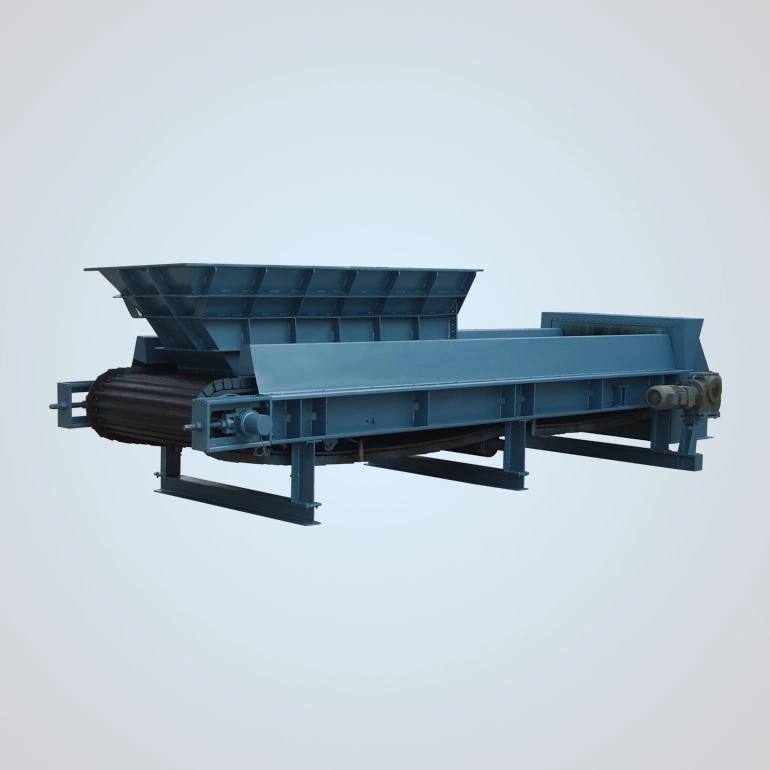

WSD-LJ belt chain weighing feeder

Working Principle:

Working Principle:

The belt weighing feeder detects the weight of the material on the belt using a weighing sensor located under the weighing scale frame. This sensor measures the weight of the material passing through the belt. A digital speed sensor, installed on the tail drum or rotating device, continuously measures the feeding speed. The pulse output of the speed sensor is proportional to the belt speed. The speed signal, together with the weight signal, is sent to the control instrument of the belt feeder, which generates and displays the instantaneous flow rate. The control instrument compares this flow rate with the set flow rate and sends a signal to the controller, which drives the variable frequency drive to adjust the motor speed, achieving the required volumetric feeding.

Dual sensor measurement structure:

Dual sensor measurement structure:

Two high-precision, high-stability imported weighing sensors are used, with a left-right symmetrical layout structure, which effectively overcomes the lateral and side forces, so that the material load will not affect the measurement accuracy.

Control precision is more stable:

Control precision is more stable:

The entire conveying and weighing process is automatically executed by the program control system to control the accurate addition amount of materials during the production process.

Save pre-feeding equipment and reduce production costs:

Save pre-feeding equipment and reduce production costs:

The chain plate is embedded on a special tape, which has both the feeding and scraping functions of the chain plate conveyor and the metering characteristics of the belt feeder scale, which can save pre-feeding equipment, save users' production costs and site space.

Product Parameters

Product Parameters

WSD-LJ belt chain weighing feeder